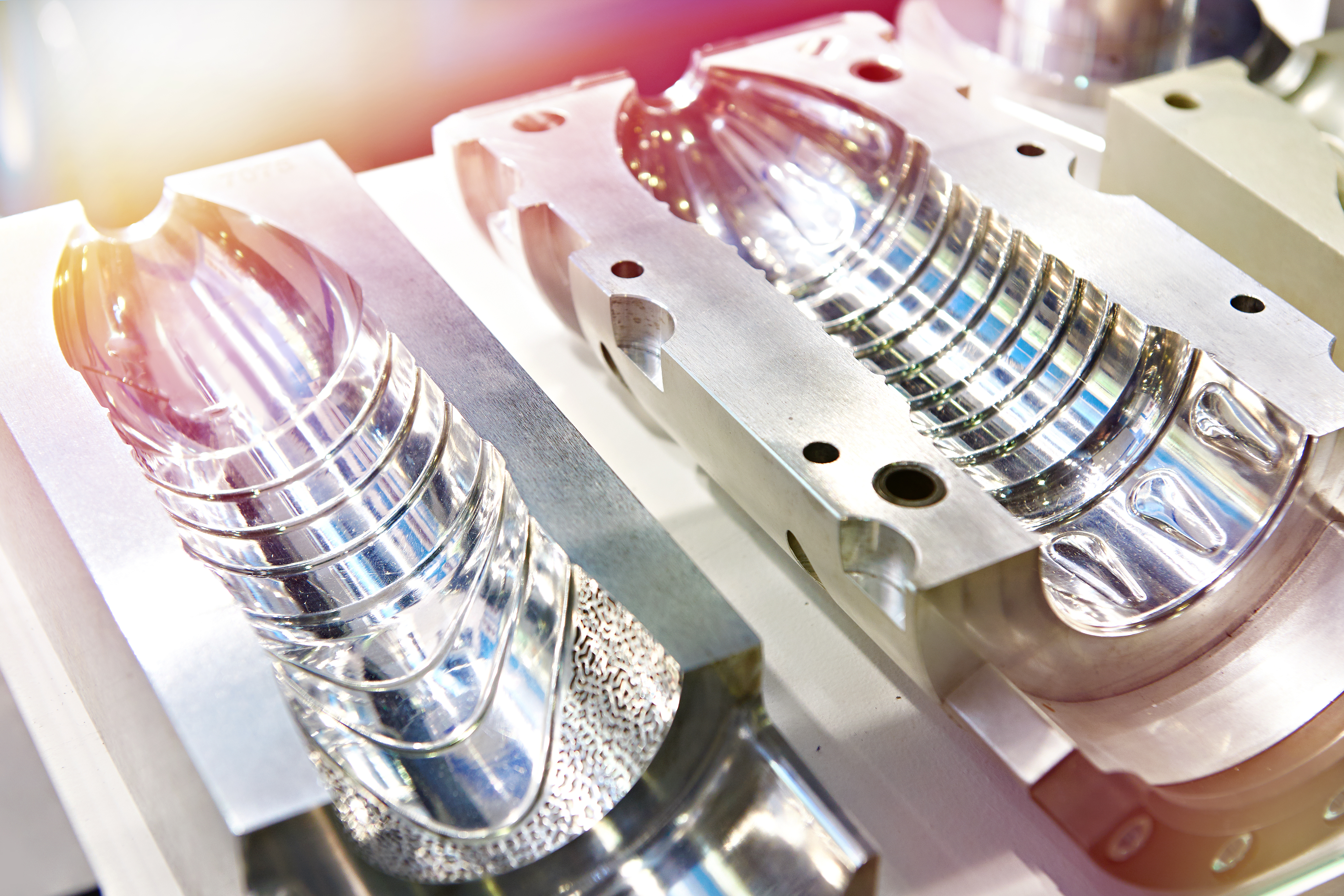

Silicones for Mold Release

CHT offers a broad range silicone and hydrocarbon wax additives as well as world class technical support dedicated to improving your release efficiency with reduced production downtime.

CHT offers a broad range silicone and hydrocarbon wax additives as well as world class technical support dedicated to improving your release efficiency with reduced production downtime.

Silicones provide an unrivaled slip and release in a variety of molding applications due to their low surface tension, low affinity for most molded materials and high temperature stability. Add to that silicone’s highly customizable crosslinking chemistries, and our silicone experts can tune CHT’s release fluids and emulsions to be purposely sacrificial, or remarkably durable.

CHT manufactures concentrates and ready-to-use silicone and wax products for the release of thermoplastics, flexible foams, rubbers, composites, polyurethane foams, food grade containers, wood (oriented strand board), tires and diecast to name a few. These different applications make use of the following CHT chemistries that are produced around the globe:

- Hydrocarbon wax emulsions (Keim Additec line)

- Low molecular weight polydimethylsiloxanes (PDMS) - 50-1000 cSt

- Moderate molecular weight PDMS – 1000-60,000 cSt

- High molecular weight PDMS – 100,000-500,000 cSt

- Ultrahigh molecular weight PDMS – 1,000,000 – 120,000,000 cSt

- Highly crosslinking elastomeric PDMS

- Cationically charged PDMS

- Amine-modified PDMS

- Silsesquioxane resin + PMDS

- Emulsions of the above

SILICONE EMULSIONS IN FOOD GRADE APPLICATIONS

Silicones that have been emulsified with FDA-approved ingredients have widespread use in food grade (FG) applications. CHT’s world class emulsification technology affords ultrastable products using these additives, and our technical staff can assist in selecting the most effective product for your specific food grade application. Our current FG product line has been developed to solve our customers’ food and food processing issues with thermoformed package denesting, slip aids, paper hydrophobing, antifoaming and food release. Bring your food-related manufacturing and packaging concerns to CHT’s silicone experts and let us customize an efficient FG emulsion for your application.

Silicones that have been emulsified with FDA-approved ingredients have widespread use in food grade (FG) applications. CHT’s world class emulsification technology affords ultrastable products using these additives, and our technical staff can assist in selecting the most effective product for your specific food grade application. Our current FG product line has been developed to solve our customers’ food and food processing issues with thermoformed package denesting, slip aids, paper hydrophobing, antifoaming and food release. Bring your food-related manufacturing and packaging concerns to CHT’s silicone experts and let us customize an efficient FG emulsion for your application.

Technical Data Sheets for CHT food grade emulsions are available below.

For technical assistance or sample requests, please visit our contact page.

You can find more products for this field of application on cht.com Industry Solutions

| Product | Description | Features |

|---|---|---|

| ACC 2028MV | 20% Aminofunctional silicone microemulsion | Easy to formulate due to its fine particle size, which also delivers superior dilution stability |

| EM 1039 | EM 1039 is a water dilutable 35% silicone fluid emulsion, employed as a releasing agent for rubber and generally plastic materials. | General purpose release agent |

| EM 1144 | 60% active emulsion of ultra high molecular weight PDMS | Imparts slip and mar resistance in a high solids emulsion |

| EM 1407 | 40% Active Emulsion of a High Molecular Weight Polydimethylsiloxane | Long lasting |

| EM 1409 | 54% Active Emulsion of Amine Functional Polydimethylsiloxane | Extended performance |

| EM 1421 | 60% Active Emulsion of Ultra High MW Polydimethylsiloxane | Excellent mar resistance and leveling |

| EM 1435 | 40% Active Emulsion of a High MW Polydimethylsiloxane | Excellent wetting and spreading |

| EM 1449 | 35% Active Cationic Emulsion of Amine Functional Polydimethylsiloxane | Excellent wetting and spreading |

| EM 1463 | Food grade 350 cSt polydimethylsiloxane emulsion | Best in class dilution and formulation stability |

| EM 1475 | 40% Active Emulsion of a High MW Polydimethylsiloxane | Excellent dilution and freeze-thaw stability |

| EM 1476 | 40% Active Emulsion of a High MW Polydimethylsiloxane | Excellent dilution and freeze-thaw stability |

| EM 1478 | 50% Active Emulsion of an Ultra High MW Polydimethylsiloxane | Ultra high molecular weight silicone delivered in a high solids emulsion |

| EM 2750L | Silicone emulsion for printing | Chemically inert - will not gum up heat set printing mills |

| EM 346 | 60% actives silicone emulsion | Excellent break out with minimal stress or heating |

| ICM 1004 | Diaminofunctional Silane | Effective coupling agent |

| ICM 1005 | 100% glycidoxypropyltrimethoxysilane | Effective coupling agent |

| ICM 1076 (60) | Food grade silicone emulsion | Food grade ingredients |

| ICM 1670E | 60% active emulsion of 350cst polydimethylsiloxane | Industry leading particle size |

| ICM EM 1,000,000(50) NO NP | 50% active emulsion of 1,000,000 cSt hydroxy terminated polydimethylsiloxane | High molecular weight |

| ICM EM 100,000 NO NP | 40% active emulsion of 100,000 cSt hydroxy terminated polydimethylsiloxane | High molecular weight |

| ICM EM 421 | Ready to use ultra high molecular weight polydimethylsiloxane emulsion | Ready to use formula |

| ICM EM 60,000 NO NP | 40% active emulsion of 60,000 cSt hydroxy terminated polydimethylsiloxane | High molecular weight |

| ICM SF 725P | 50% Active Aminofunctional Polydimethylsiloxane | Detergent Resistant |

| SF 721P | 100% active aminofunctional polydimethylsiloxane | Durable and abrasion resistant |

| SF 722P | 100% active amino functional polydimethylsiloxane | Durable and abrasion resistant |

| SF 724P | 100% active amino functional polydimethylsiloxane | Durable and abrasion resistant |

| SF 725P | 50% active aminofunctional polydimethylsiloxane | Detergent Resistant |

| SF 727P | 100% active aminofunctional polydimethylsiloxane | Durable and abrasion resistant |

| SF 736P | 100% active aminofunctional polydimethylsiloxane | Durable and abrasion resistant |

| SilSo Replicate 21009 (ALPA-SIL CLEAR) | 2-part silicone moulding rubber | Crosslinks at temperatures as of 23 °C/77°F |

| TE-352 FG | TE-352 FG is a 40% active food grade emulsion of 350 cSt PDMS fluid. This product was specially formulated for food packaging applications | alkylphenol and formaldehyde free. Solvent free and chemical inert. |